XG603-1A

■ PRODUCT DESCRIPTION

Matt Hardener XG603-1A is the salts of polycarboxylic acid with cyclic amidine. The hardener, applied in suitable formulations can produce epoxy or Hybrid coatings for matt or semi-matt gloss with very good flow and properties. Variation between matt and semi-matt surface can be obtained by means of suitable adjustment of formulation

■ PHYSICAL PROPERTIES

| |

UNIT |

TYPICAL VALUE |

MIN |

MAX |

TEST METHOD |

| Appearance |

|

White Powder |

|

|

|

| Melting Range |

℃ |

|

222 |

227 |

|

| Non Volatile |

% |

|

98.5 |

|

|

■ Application

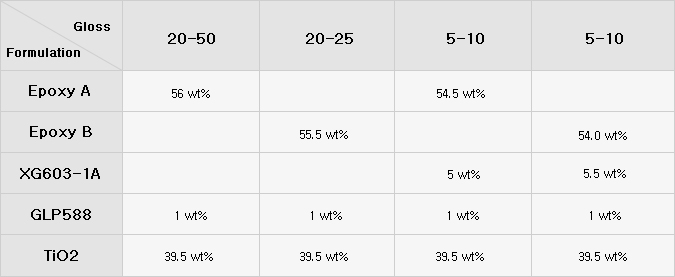

The hardener may be applied both in pure epoxy and hybrid (epoxy-polyester) resin powder coatings. Epoxy coatings of gloss range level ranging from 5%~10% and hybrid coatings with gloss levels ranging from 10%~70% ( or greater ) may easily be formulated by the use of XG603-1A. Coatings produced with XG603-1A are characterized by color and gloss stability under normal baking conditions. Hybrid coating with matt or semi-matt gloss may be achieved by replacing some of the polyester in the formulation with an equivalent quantity of XG603-1A.

The following gives the formulations of hardeners for matt epoxy coatings.

*Epoxy A: EEW850-1000; Epoxy: EEW 700-850

**GLP588 is a leveling agent with silica carrier available from Ningbo south sea chemical Co., Ltd. It's noted that the achievement of matt effect and relevant properties of the film is connected with full cured of coatings. Thus, the following cure schedules are recommended.

| Object temp |

Time |

| 180℃ |

20-25min |

| 190℃ |

12-15min |

| 200℃ |

10-12min |